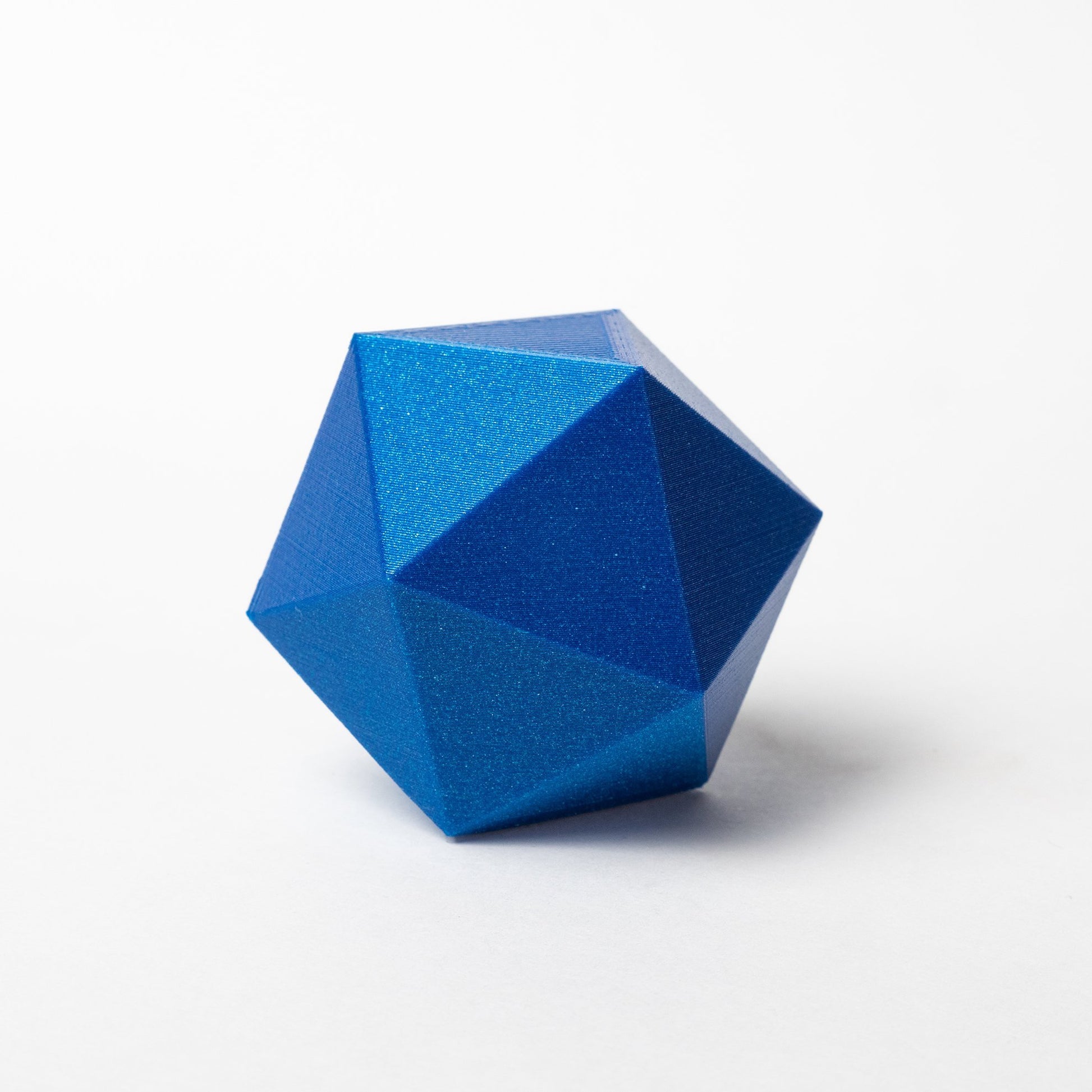

Joel's Highfive Blue HTPLA

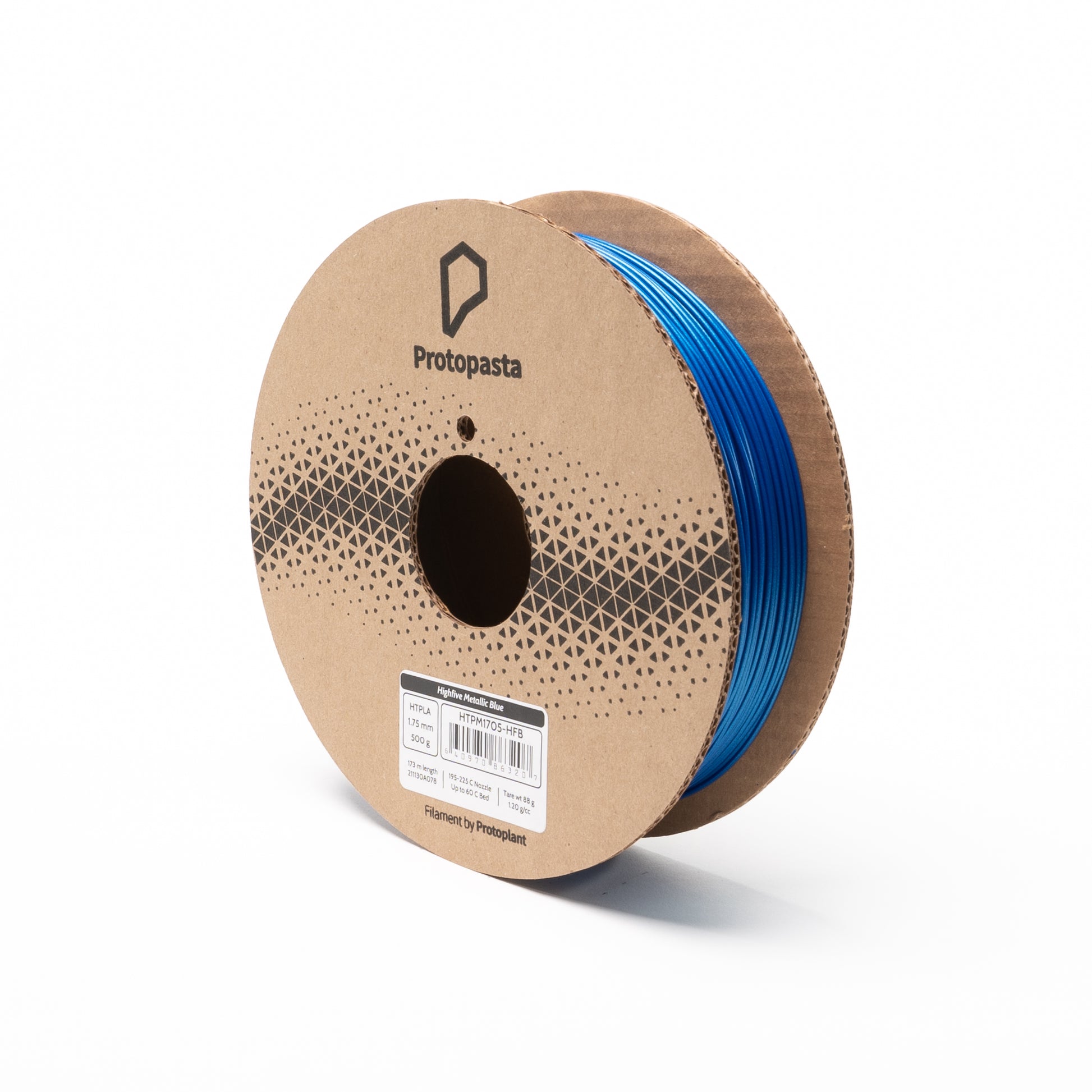

SKU: HTPM170-HFB

Fellow 3D Printing Nerds, we are fans of Joel Telling just like you! We'd all love to capture a bit of his energy, right? Rather than bottle it, seems more appropriate in filament form, don't you agree? The metallic finish is indeed energetic, and it's Joel's favorite color, blue! Yes, Highfive Blue HTPLA is awesome. Even more awesome is that a portion of sales support Joel's favorite charity, Seattle Children's Hospital.

Technical Data Sheets

Technical data sheets available for download here.

Safety Data Sheets

Safety data sheets available for download here.

Shipping

We provide a number of domestic shipping options within the United States via UPS, including free shipping on orders of $50 or more. We also provide international shipping via DHL Express.

Returns

At ProtoPlant's discretion, returns and replacements will be accepted within 90 days of purchase. Please check the material label before opening your product. Only sealed product can be returned. Shipping of items for exchange or refund is paid by the customer. More information about returns and replacements can be found in our terms and conditions.

Fleck 'n fun with Joel Telling!

- Our 1st metallic finish filament & 2nd sparkly release after Stardust

- In collaboration with content creator 3D Printing Nerd, Joel Telling

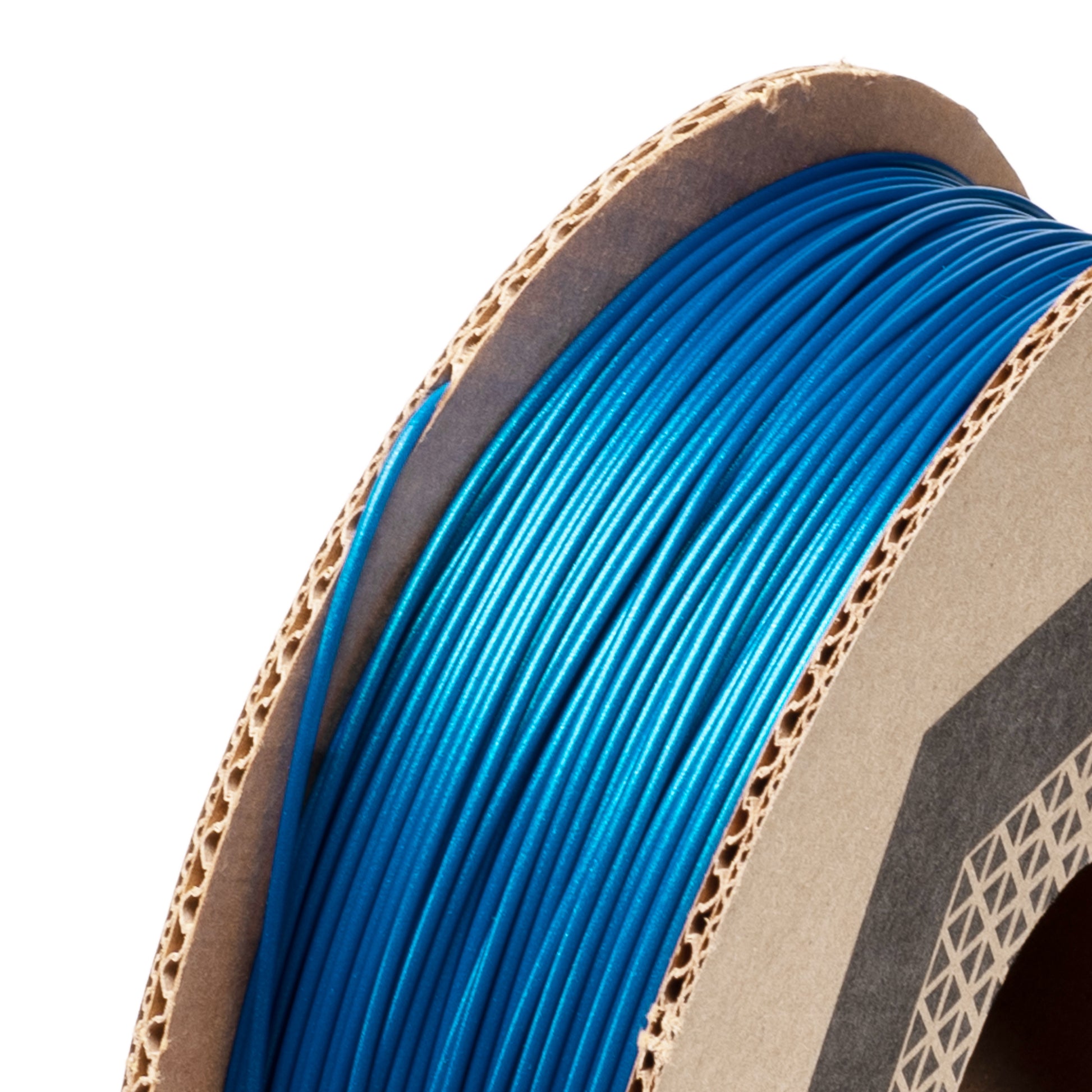

- Joel's favorite color, blue, with medium silver fleck in HTPLA

- Medium fleck brings balance of layer-hiding texture & detail

- Premium HTPLA for world-class quality, finish & performance

Specs

Semi crystalline, heat treatable PLA for high temp use

Density: 1.24 g/cc

Length: 346 m/kg (1.75) 130 m/kg (2.85)

Typical Printing Temp: 205-225 C

Glass Transition (Tg)*: 60 C

Peak Crystallization (Tc)**: 95-115 C

Onset to Melt (Tm)***: 155 C

Typical change when heat treated: -2% x/y +1% z

Link to Safety Data Page

*max use with no heat treat & max platform temp

**heat treating @ temp 10+ min depending on size/mass

***max use when heat treated (annealed or crystallized)

HTPLA prints well at 205-225 C, however it's important to match temp to

your hardware & volume flow rate. With a typical hotend, you should be

able to print at 205 C without jamming at a low flow rate. In machines

with hardware that tends towards jamming, consider this

video with Joel Telling.

Lower volume flows require lower temps, while higher volume flows require

higher temps. In the previously-mentioned video, one way to overcome

jamming is to set your temp to a higher-than-typical 240 C. This should

then be matched with a high flow rate for a quality printing result.

For direct drives with a short distance between drive gears & nozzle,

volume flows can approach 7-8 cubic mm/s or more if printing hot to

overcome jamming. For bowden tubes where the distance between drive gear

& nozzle are great or less powerful hotends, as little as 2 and as

much as 4 cubic mm/s may be the limit. Beware of unintended speed changes

from faster infills & slowing down for outlines or short layers.

Consider our Ultimaker-specific blog for more on this topic.

A constant speed throughout the part is ideal from an extrusion

perspective. Knowing your extrusion width, layer thickness & speed you

can calculate your volume flow rate with the calculator like found in the

previously-mentioned Ultimaker blog. Alternatively, if you know your

volume flow rate limit, extrusion width & layer thickness, you can

calculate your speed limit.

Heat Treat

PLA & HTPLA are amorphous in structure as printed (no heat treating)

& though both are adequate performers in an office environment, they

have poor temperature stability, loosing significant stiffness at temps

nearing 60 C. Different than standard PLA, HTPLA is designed to survive

heat treating for higher temp stability in a no/minimal load condition to

near onset of melting (155 C). That's an astonishing improvement in

thermal stability compared to standard PLA after a quick bake in the oven

after printing.

In as little as 5-10 minutes for small, thin parts, HTPLA quickly

crystallizes in an oven at 95-115 C (200-240 F) to become more stiff &

hold form above glass transition (60 C). Depending on part geometry, setup

& technique, parts can deform and shrink. Best results are with flat

and/or supported parts with 100% infill. In this instance we experienced

x/y shrinkage of about 2% & growth of about 1% in z.

Be sure to avoid hot spots (non-radiating surfaces & no glowing coils)

in the oven used for baking & experiment before baking a prized part.

Un-printed filament works great for experimentation & translucent

makes the transformation most visible! Heat treating is an art, but the

resulting improved thermal performance, if needed, is well-worth

exploring. You'll be shocked by the improved thermal stability of your

HTPLA parts!!!

Links

Material Safety Data

Blog

about heat treating

Heat

treating application blog

Avoiding

Jams on your Prusa blog

Avoiding Jams on your Prusa video

Tuning

for your Prusa blog

Tuning

for your Ultimaker blog

Tuning

for your Lulzbot blog