Does your printer stop extruding on the first layer? Or does it clog later in a print? Is your print quality inconsistent with missing cross-sections? Or does your printer fail on small, intricate cross-sections especially when printing slow?

If your extruder gear ever grinds or slips on your filament, you’ll want to read below!

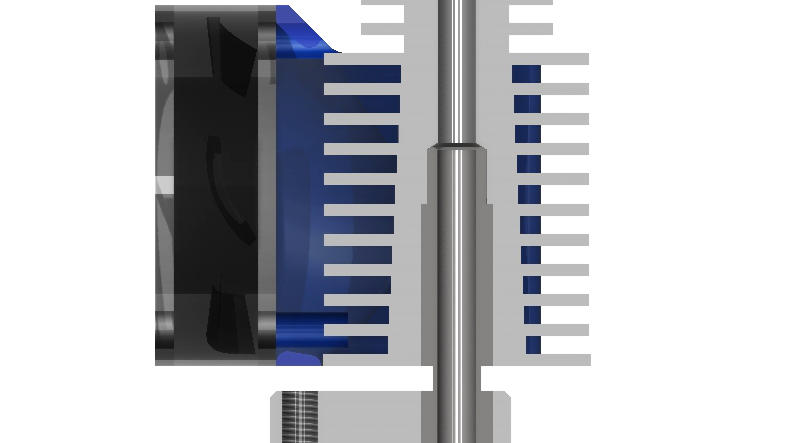

Jams and clogs are often from a combination of excessive heat and non-optimal material flow. This effect is worsened by poorly cooled all-metal hot ends, high torque extruder gears, small nozzles/layers, slow printing speeds, too thin first layer, and excessive retraction.

To get more reliable results with PLA composites and all-metal hotends in particular, consider the following:

- Check fans. Make sure your hotend fin cooling fan (the fan above your nozzle, different than your layer cooling fan) is clean, clear of obstruction, and functioning properly. This fan is typically ON when your nozzle is on and hot.

- Print faster. Increase print speed to avoid heat soak. Slow printing means more time to absorb heat. Too much heat can prematurely soften the material so it gets compressed and drags on the hotend inner walls. For example, avoid speeds less than 10mm/s. Remember, PLA materials get soft just above 50C even though they melt at a much higher temperature.

- Lower resolution. Choosing thicker layers can also help print faster, with higher mass flow rate. Choose a minimum 0.15mm or 0.2mm. Again, keep the material moving to avoid getting too warm and soft.

- Print cooler. Print with the lowest possible temperature for good layer adhesion. For HTPLA, this is typically 215-220C but can be hotter or colder. For more thermally conductive PLA composites like Iron, this can be as low as 180C.

- Adjust flow. Decrease your flow setting to balance flow and avoid forcing too much material into your hotend. Excess material is compressed and expands to create friction inside the hotend. When this happens, the flow setting may seem too low because not enough material is coming out of the nozzle, but increasing the flow setting can make the problem even worse. With more excess material in the hotend, flow gets worse when the extruder feed gear exerts even more pressure. Eventually the gear slips and grinds against the filament. The solution is not pushing harder, but decreasing the flow setting and/or removing restriction.

- Remove restriction. Replace your small nozzle with a larger one. For example, use 0.6mm or 0.8mm instead of 0.5mm or smaller. Small nozzles can reduce and resist material flow. Larger nozzles are more forgiving. Also, avoid first layer gaps that are too small as they create a similar restriction but only on the first layer.

- Minimize retraction. With balanced flow and less restriction, you shouldn't need too much retraction as there won't be much pressure to relieve with good settings. Excessive retraction rarely fixes drooling/stringing problems and just moves melted plastic into the part of the hot end where it is not supposed to be, causing jamming.

- Maintain temperature. Now that you are pushing more plastic, make sure your actual printing temperature is equal to your set temperature. Can't maintain the set temperature? Reduce your print speed until the actually temperature is stable and matches the set point!

- Add lubrication. When all else fails (or you're tired of tuning), lubricate. It's also a good recovery tool after jamming because once a hotend jams and deposites melted plastic where it shouldn't, it's more prone to jam again. To lubricate, apply a thin film of mineral or vegetable oil on the filament surface is a more of a bandage, but makes the material slippery enough to keep compacted filament moving inside a sticky all-metal hotend. A little oil goes a long way to make up for a lack of PTFE liner. Apply oil to your filament before inserting into the hot end, and then maintain with oil dabbed on a paper towel or sponge wrapped around your filament in between the drive gear and filament spool. This is highly effective but also easy to overdue. An invisible film of oil on the filament is sufficient. Also, long-term hotend performance and influence on layer adhesion, for example, are questionable, but when all else fails, a little oil is highly effective and can save HOURS of headache messing with settings. Try at your own risk.

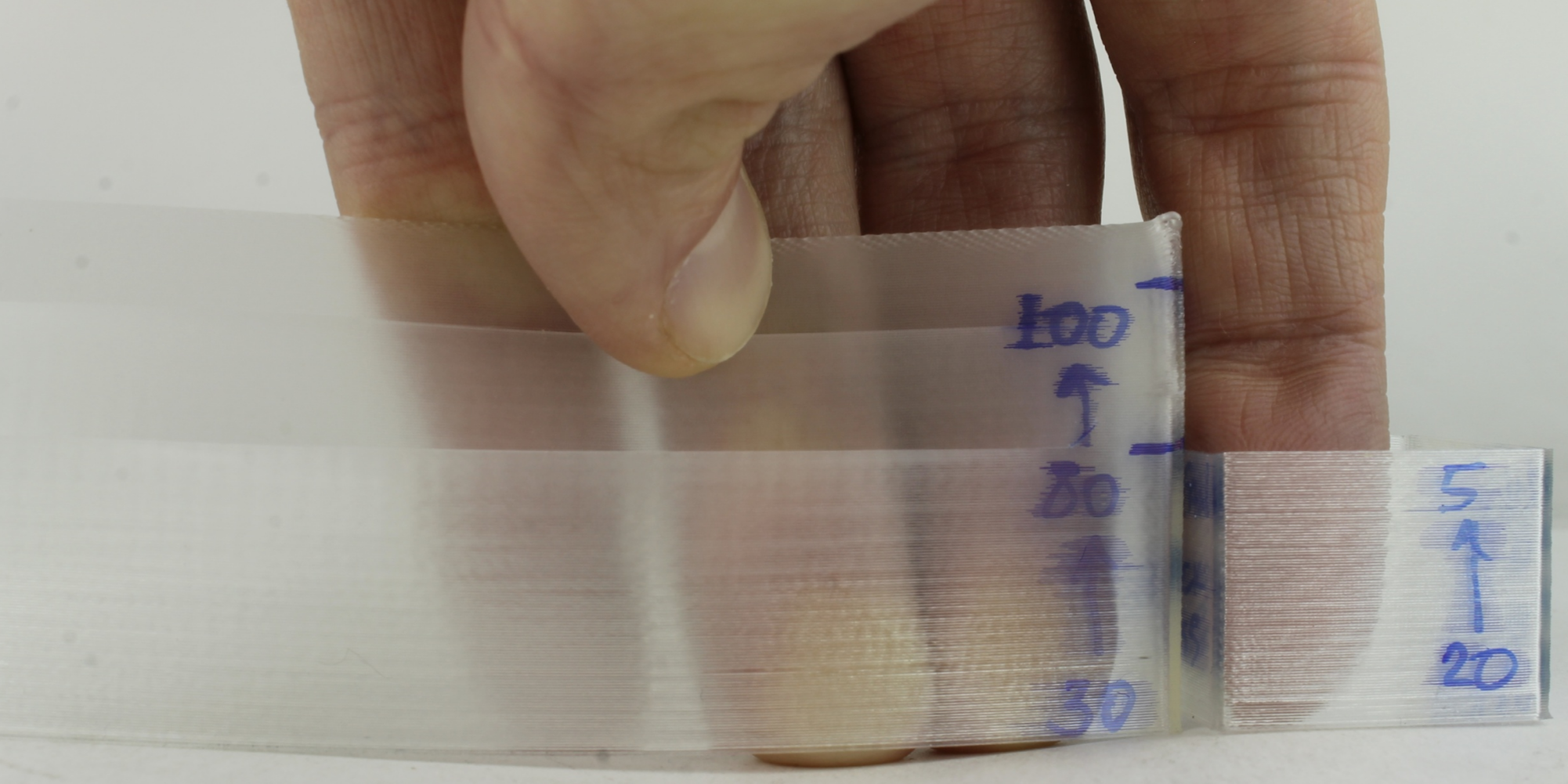

- Heat treat. A last resort with no turning back, but sure to cure filament softening from too much heat and force with some downsides. Filament, especially composites, can become more brittle (so much as to create breaking during printing with a poor spool mounting position). The glue on our cardboard spools can become brittle and fail. Also, the filament requires more energy to melt which, if not enough heat is provided, can again result in inconsistent printing. To heat treat, preheat your oven to a stable temperature with no glowing heating elements. You can also shield any radiant energy with Aluminum foil. Make sure your filament is wrapped tight (like with plastic wrap as delivered from Proto-pasta) and bake at 200-225F for 3+ hours. More time (overnight for example) is okay.

- Back to basics. Still having trouble? Get back to basics with a benchmark print in standard settings and material you are most familiar with just to make sure your machine is still operating as expected!

Some additional thoughts...

A high temperature and slow speed for the first layer, while best for adhesion, can create a worst case scenario for heat creep. In some cases, your layer cooling fan can also be cooling your nozzle so you may need to decrease your fan speed or turn it off entirely to maintain nozzle set point. Reduced layer fan can, however, compromise surface quality.

If you’ve had grinding, make sure the extruder gear is clean and clear for a fresh start to avoid cascading failure and compounding frustration. You can push the material by hand when the nozzle is hot to get a feeling for whether the material is flowing freely.

And remember, conservation of mass! FLOW INTO THE HOT END MUST EQUAL FLOW COMING OUT OF THE NOZZLE. FLOW IS LIMITED AND YOU CANNOT PUT MORE MATERIAL IN THAN WILL COME OUT!

Hopefully, you find this informative and helpful in wrangling your hot end for non-stop, reliable printing. Good luck!